What are Cantilever Stairs?

Cantilever stairs offer a stunning “floating” effect, with stair treads that seem to hover unsupported in mid-air. To achieve this look the stair treads may have a hidden steel structure embeded within or beneath the treads for support. In addition, the steel support structure and stringer may be concealed in the wall for a sleek minimalist look or be exposed for an industrial aesthetic. The stringer and steel structure are typically located on one end of the treads. Understanding the required weight-bearing load on the treads is critical to engineering a cantilever stair system that minimizes flexing. Expertly engineered and artfully designed a cantilevered stair can add an element of interest and spaciousness to your home.

Creating cantilevered stairs starts with measuring the site, understanding the structure of the building, and existing load-bearing walls. To accommodate a cantilever staircase it may be necessary to build more strength and support for the stairs into the walls. Once this is understood creating an exact drawing for the stair fabrication is essential. Also, it may be necessary to run stress analysis on the structure. By understanding the site and the construction of cantilever stairs, you can create a unique structure that will optimize performance, safety, and style.

1) Hidden Cantilever Stair Stringer and Structure

This project was designed to hide the stringer and support structure inside the wall. Three structural steel tube posts run from floor to ceiling concealed within the wall with an 8-inch steel stringer attached diagonally. At the top of the stairs, a square steel framework supports the landing and is encased with wood. Each tread has a double steel structure wrapped with oak to hide the steel system within it, resulting in a genuine work of art.

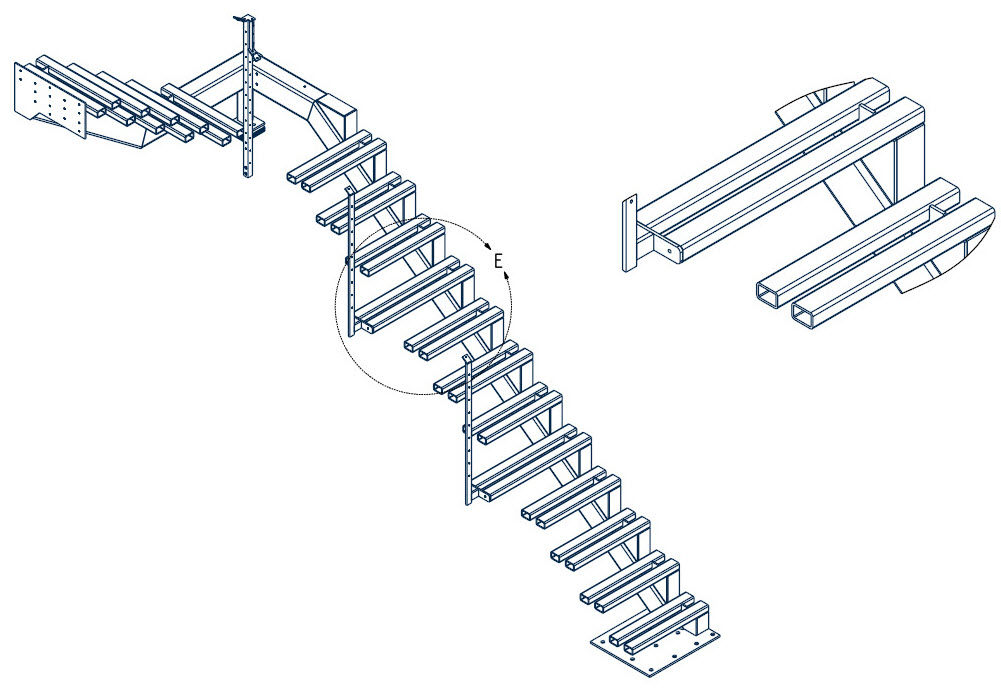

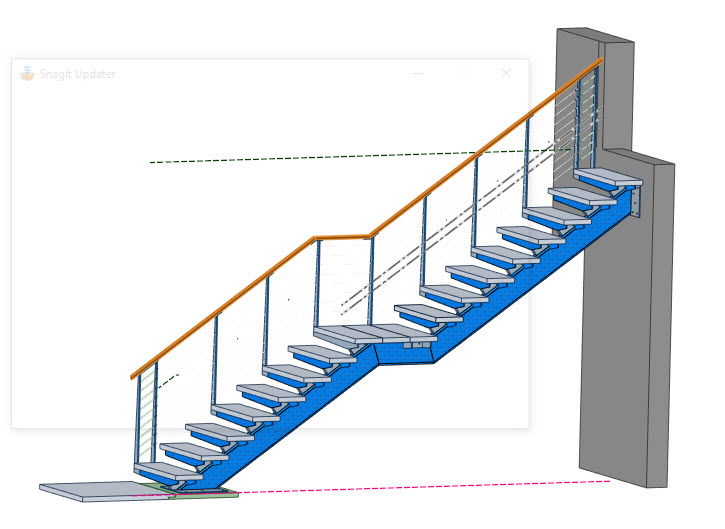

2) Exposed Cantilever Stair Stringer and Landing

This staircase was custom crafted with the steel stringer partially exposed through the shiplap finished wall. Each stair tread is supported by an exposed structure creating an industrial styling that appears to zig-zag up the wall. To create the platform landing the stringer wraps around the corner while maintaining the exposure. Each railing post slices through the treads, concealing the attachment hardware below the tread.

Additionally, steel attachment plates were added to the top and bottom of the stairs and hidden in the floor and wall. These plates adds strength to stairs while providing the function of resisting torque. By understanding the torsional load on the wall a number of techniques can be used such as adding hidden attachment plates.

3) Partial Cantilever Stair with Stone Steps

This staircase leading from a garage entry to an upper-level pool and patio was designed with the stringer biased to one side along the concrete wall. Thus, establishing the look of a cantilevered stair while maintaining the strength and resistance to the torque that is required.

With stone stair treads the strength of the staircase cannot depend on the stone tread to support and resist the torque of the staircase. Therefore, each tread support required a sufficient steel structure to prevent the stone step from cracking. The tread supports were designed with threaded rods welded to the support and projecting upwards into the predrilled stone tread. This approach solidly anchors the tread to the steel tread support.

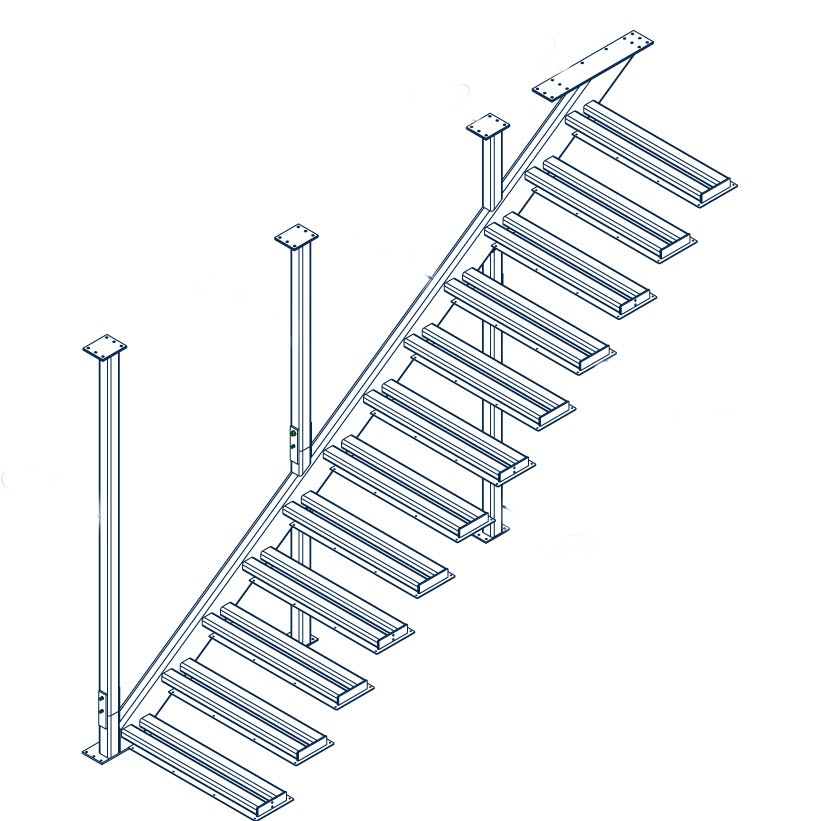

4) Fully Exposed Exterior Cantilever Stair

This home features a fully-exposed cantilevered staircase transitioning from the deck to the yard. Choosing thin Ipe treads for this staircase required the steel structure to be strong enough to support the thin treads. Furthermore, the deck structure was reinforced to support the stringer. Note that the stringer switches sides at the platform level to share the steel support post and cantilever the landing.

The design uses cable railings to maintain the open appearance and the posts connect seamlessly to the steel tread supports below the IPE. Also, the deck and steel posts are further supported by extra footers below ground.

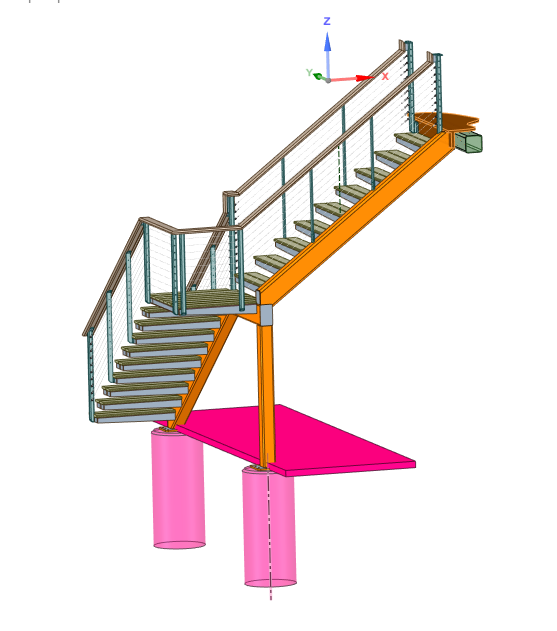

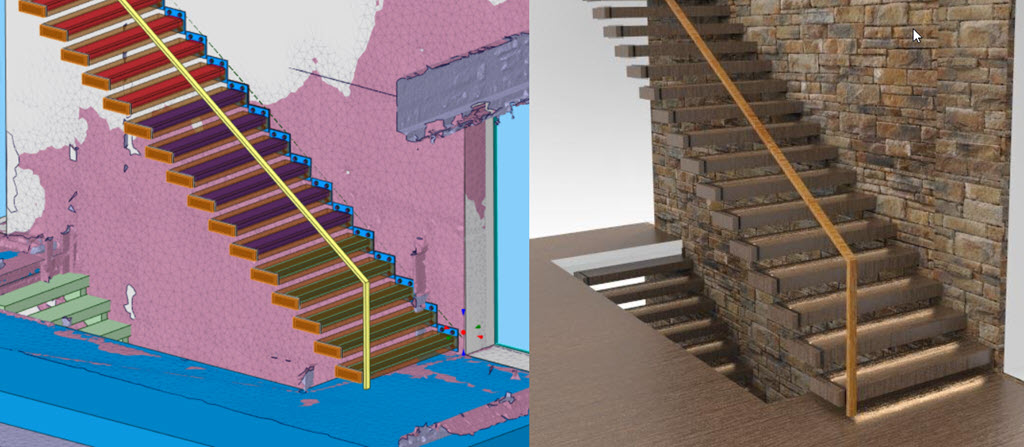

5) Digitally Measuring, Rendering and Analysis

Digitally measuring the site provides accurate scan data which supplies critical pieces of information for the design, such as how parallel the building walls are to the floor. Using these measurements ensures the cantilever staircase will fit and function as required. Creating a rendering of the finished stair before fabrication allows for visualizing proposed decorative finishes. This helps to finalize the design before producing the final product.

Stress analysis of cantilever stair exaggerating deflection

At Keuka Studios, we custom fabricate residential and commercial stairs and railings to fit your style, space, and requirements. To learn more about how each project moves from vision to reality, see our custom railing design process. We take pride in building craftsman-quality and commercial-grade stairs and railings for interior and exterior applications. Get in touch to start your project with us!.